Preambule

There are a number of LED lightings available for operation in explosive atmospheres. These lighting devices such as lights, projectors, street lamp smust follow ATEX directives and standards if they are intended to be used in an ATMosphere Explosible zone or ATEX. These ATEX lights are generally very expensive to respect these environmental constraints, there are fortunately fiber optic lighting alternatives.

LED lighting in ATEX zone

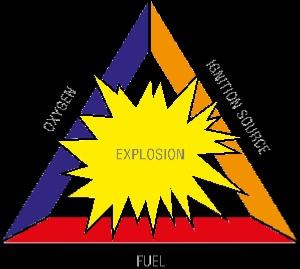

An ATEX zone is defined according to its degree of danger. It is linked to an atmosphere explosible characterized by a mixture of flammable substances with air. This mixture may consist of gases, vapors, mists or dust. After ignition of this mixture, the combustion spreads to the whole of the unburned mixture.

The types of blast can be linked to a chemical reaction, the sudden rupture of a pressurized container with the release of a large amount of energy stored under pressure or the ultra-rapid vaporization of a pressurized and superheated liquid.

For an explosion to take place, a number of conditions must be met, such as the presence of a fuelin a given concentration in the air, associated oxidizers making combustion possible, associated confinement and a source of ignition. (electrical,electrostatic, thermal, chemical, bacteriological, etc.

The complexity of LED lighting in an ATEX zone is designed to prevent it from becoming a source ofignition, knowing that excessive heat can cause explosions or ignition. This complexity usually results in the high cost of its lighting fixtures.

Interest in fiber lighting / backlighting in an ATEX zone

An advantageous alternative solution is to take into account fiber optic lighting by deporting the light source outside the ATEX zone

This source then no longer needs to respect temperature thresholds and no longer entails any electrical risk linked to a spark. The light is then transported to the ATEX zone by a bundle of luminous optical fibers. The optical fiber has the quality of transmitting light, of not generating electromagnetic disturbance, of not generating heating at the end of the fiber.

Thanks to its intrinsic qualities, luminous optical fiber is the best candidate for lighting in ATEX zones in environments as different as the food industry, miningindustry, petrochemicals, industrial painting, etc.

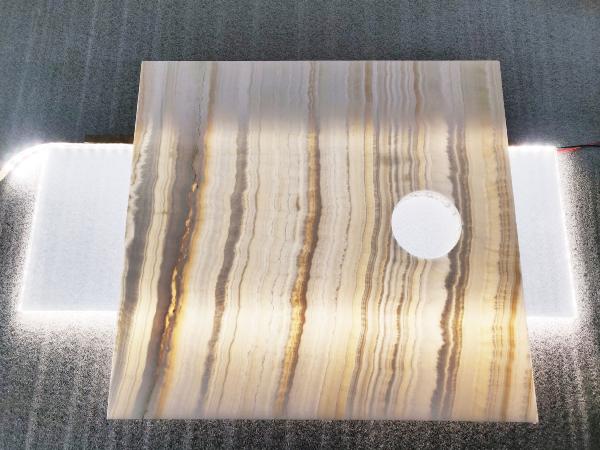

The use of the luminous fiber allows in ATEX zone either to illuminate a point of interest in the space or to backlight a transparent or translucent surface

Implementation of fiber lighting in ATEX zone

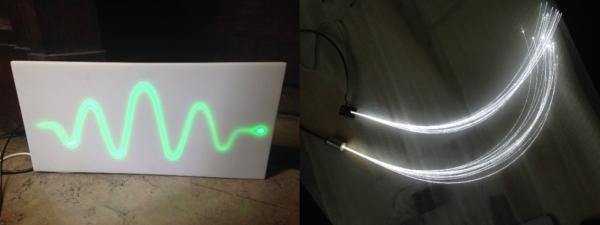

Luminous fiber lighting includes the harness with a light cable or several light cables, connected to the light source by a common collector. Each light cable consists of several plastic optical fibers.

As for the connection with the light source, it is done in a safe place outside the ATEX zone where the light source is located. Lighting in an ATEX zone can be done through spot lights which will be fixed at the end of the light cables or via a strip with a certain spacing between the fibers to illuminate an area.

Implementation of fiber backlighting in an ATEX zone

Fiber backlighting in an ATEX zone is quite possible by placing diffusing fibers to highlight an outline thanks to the lateral lighting of the fiber or to illuminate a transparent or translucent plate. In this case the diffusing fibers are placed in a bundle with a common collector connecting to the light source outside the ATEX zone.

Another backlighting solution in an ATEX zone consists of illuminating a transparent plexiglass plate. This plate would be treated so as to diffuse a completely homogeneous light over its entire surface if it is illuminated on its edge. A sheet of luminous optical fibers inserted in a strip would illuminate the edge of the plate to be backlit. This plate could also be engraved to bring out a pattern.

This plate could also be engraved to bring out a luminous pattern.