Propagation modes within polymer optical fiber

A plastic optical fiber with index step consists of a transparent PMMA(Polymethyl Methacrylate) core and a cladding of fluorinated polymer with a refractive indexlower than that of the core. The confinement of light within the fiber is donethanks to the phenomenon of total internal reflection.

Fibers supporting many propagation paths for light or transverse modes are called multimode fibers as opposed to single mode fibers which only support one mode.

Optical fiber is a waveguide which exploits the refractive properties of light. A step index optical fiber is also characterized by its numerical aperture NO which defines the maximum angle of light at the entry of the fiber for its reflection within the fiber, namely the aperture of the acceptance cone . The theoretical value of the numerical aperture is calculated according to the refractive indices nc of the heart and ng of the cladding :

PMMA refractive index is around 1.49. The refractive index of the cladding ngis always slightly lower than the refractive index of the core nc.

One can also determine the number of modes which can propagate in the plastic optical fiber thanks to the normalized frequency V. This normalized frequency depends on the wavelength in the vacuum 𝛌, on the radius of the core of the fiber as well as on the NA digital aperture ofthe fiber. It can be calculated by the following formula:

A fiber becomes single mode for a normalized frequency V less than 2.405.We see that the large optical plastic fibers in the visible range can only behave in multimode fiber. In a multimode step index fiber, the number of modes is approximately equal to V2/2.

Light cone at plastic optic fiber output

It can easily be shown that the light cone at the fiber output isequivalent to the acceptance cone at the fiber entry, that is to say itsnumerical aperture.

As shown in the figure below, the larger the digital aperture of the fiber,the larger the light area at the output of the fiber.

For a 0.5 digital aperture of a standard plastic optical fiber dia 1mm, we calculate an acceptance angle of 60 °. We can deduce the diameter of the lightcircle at 50cm from the fiber; its value is 58cm.

Taking this time a large numerical aperture of 0.64, the acceptance angle goes to 79 °, the diameter of the light circle at 50cm from the fiber goes to 82.5cm. It is shown that the lighting surface of a fiber with a numericalaperture of 0.64 is 2 times higher (the coverage radius is high squared) than a fiber with a numerical aperture of 0.5. The two drawings below clearly show the differences in the lighting area at the fiber outlet depending on the digital aperture of the fiber.

Bending radius of polymer optical fiber

A bending greater than the bending radius of a fiber causes refraction of the optical signal and leaks through the cladding. This means attenuationon the light signal.

For light to escape into the heart, the angle of refraction Θ1 of the light must be less than the maximum limit refractive angle Θmax. This maximum limit angle is found thanks to the Snell-Descartes law and is expressed as: Θmax = arc sin (ng / nc).

We can see that when the numerical aperture increases, the maximum limitangle decreases. This then reduces losses by bending; in this case the radius of bending of the fiber has then decreased.

Large numerical aperture plastic optical fiber from the Toray brand

Toray produces a full range of plastic optical fibers, including fibers with large digital apertures. The table below gives the numerical aperture ofT oray fibers according to their grades.

Toray defines the bending radius of the fiber when it induces 20% loss inthe fiber (corresponding to a loss of 1dB). Toray compared the fiber bend radii with numerical apertures of 0.5 (standard) 0.64 (wide aperture). We see that a fiber dia 1mm has a bending radius of 5mm for a numerical aperture 0.64 against9mm for a standard numerical aperture 0.5.

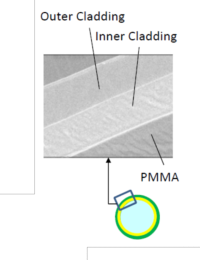

On the other hand these fibers with large numerical aperture have otherqualities, this comes from the structure of the cladding with two layers against 1 single layer for a standard fiber as shown in thediagram below.

This type of fiber increases resistance to surface damage thanks to itsouter cladding layer. This type of fiber is more resistant to certain chemical components, inparticular acrylic adhesives.

This type of fiber increases resistance to surface damage thanks to itsouter cladding layer.

Toray has developed a specific PQE fiber quality (large numerical apertureat 0.64) exclusively for medical use, particularly for endoscopy (odontology,ophthalmology, orthopedics, pneumology and urology) and ophthalmic surgicallighting (laser probes and light probes) .

For uses other than medical, Toray has developed a specific quality of PHfiber equivalent to the quality of PQE fiber.

Please consult our bare polymer optical fibers, our polymer optical cords, our light guides of the Toray brand.